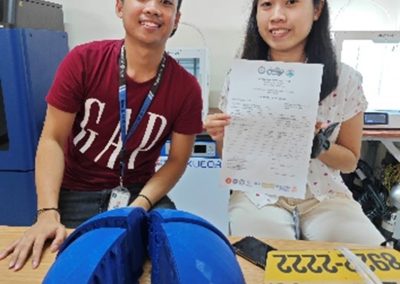

Electronics Engineering students of Universidad De Dagupan (UDD) have visited the laboratory. They availed 3D printing services and consultation regarding their project study which gathers water sample and tests its algae content. The part covers electronic components and is submerged under water majority of the time. This showcases the characteristics of 3D printing technology that it is water proof. For additional safety, the part is to be covered with marine epoxy. The meeting has concluded and the researchers will revise their design and will return on November.

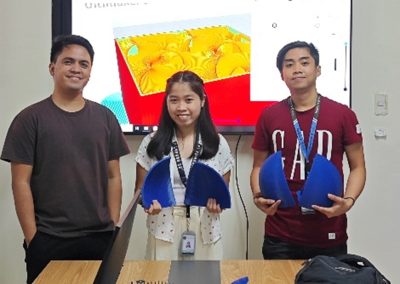

In November 17, 2023, researchers from UDD returned with their revised design. Their design is a hemisphere. This imposes a challenge on 3D printing because of its curvature, the resolution of the printers is tested.

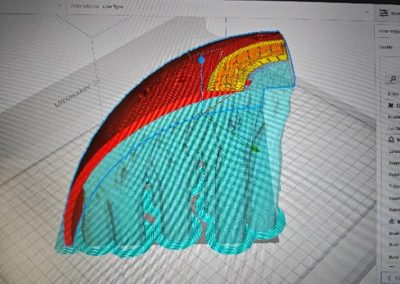

In order to lessen print cost and time, the support used in this project is tree support. Durability of the print is not a problem since infill density is at 20% and marine epoxy will be used to reinforce the print.

The researchers chose Acrylonitrile Butadiene Styrene (ABS) plastic for their research. This is because ABS plastic is tougher and lighter than PLA, making it a better option for prototyping type of projects. The whole print has lasted for two days.